|

|

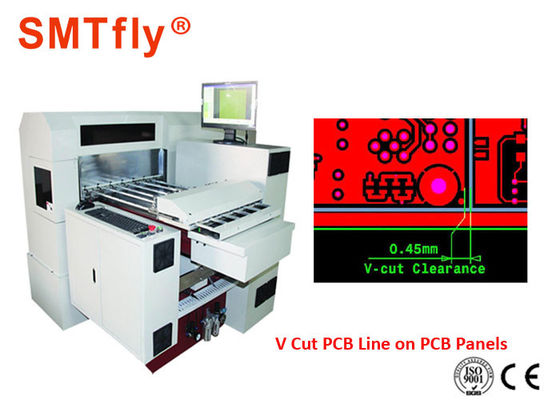

0.4 Mm - 3.2 Mm V Grooving Machine For Pcb Panel ±0.05mm Pitch SMTfly-YB630

Product Details:

Payment & Shipping Terms:

|

| Processing Thickness: | 0.4mm~3.2mm | Residual Thickness: | ±0.05mm |

|---|---|---|---|

| Pitch: | ±0.05mm | Processing Speed: | 0-40m/min |

| Min Processing Size: | 105mmx105mm | Weight: | 1500Kg |

| Highlight: | v grooving machine for pcb,v groove cutting machine |

||

PCB Scoring Machine 0.4 mm - 3.2 mm PCB Cut V-grooving Line,SMTfly-YB630 Specifications:

| Max processing size | 630mmx630mm |

| Min processing size | 105mmx105mm |

| Processing thickness | 0.3mm~3.2mm |

| Processing position | from the origin to the first knife up to 7.0mm or more |

| Processing pitch | setting within parameters,Full-closed loop auto-correction function |

| Number of jumps | set in the parameters |

| Processing accuracy | Residual thickness±0.05mm |

| Parallel | ±0.05mm |

| Pitch | ±0.05mm |

| Processing speed | 0-50m/min |

| Machine size | 1850(W)x2000(L)x1400(H) |

| Machine weight | 1500kg |

Making V - Cut Line On PCB Panel V PCB Scoring Machine Electronic Control System Introduction:

Upper and lower cutters adopt Mitsubishi servo motor with 3μ precision;

Maximum speed 3500rpm Maximum output power 200W;

Push plate axis adopts Mitsubishi servo motor specification accuracy of 3μ;

Maximum speed 3500rpm Maximum output power 400W;

Cutter shaft adopts Japan Mitsubishi servo motor specification accuracy is 3μ;

Maximum speed 3500rpm Maximum output power 700W;

The upper and lower grinding wheels adopt Japanese Fuji servo motor with the specification precision of 5μ;

Maximum speed 8000rpm Maximum output power 400W;

PLC module controller adopts six-axis motion control;

Its control stability is high.

PCB Scoring Machine 0.4 mm - 3.2 mm PCB Cut V-grooving Line Application:

SMTfly-YB630 automatic V-CUT machine, suitable for PCB molding processing.

Stable performance, high cost performance, get the majority of customers affirmed.

PCB Scoring Machine 0.4 mm - 3.2 mm PCB Cut V-grooving Line Features:

Software introduction:

System data and PC integrated management;

Processing data transmission completed in 10 seconds;

Chinese operation interface circular operation is simple;

Processing data file management up to tens of thousands of pens;

With processing data search function and delete function.

Non-board full-scale tester:

This machine adopts West German set of pin action process;

Humanized operation flow makes processing more smooth.

Production board function:

With ergonomic operation height, the operator can be more handy;

The height of the main body of the machine can make the operator more comfortable;

The main structure of the machine is relieved of stress and strengthened with steel to increase stability;

The entire process is highly accurate, yields amazing, and increases efficiency.

Gripper function description:

This machine uses seven independent cylinder type jaws;

Can adjust the cylinder flow rate;

The space nail is precision ground 2.25~3.20mm;

Can be used as a set of pin dual purpose;

Automatic stripping function.

Contact Person: Sales Manager

-

3.0KW PCB V Groove Cutting Machine , 220V Cnc V Grooving Machine TBI/THK Screw

-

V Groove Line Making PCB Scoring Machine Highly Automated SMTfly-YB1200

-

High Performance PCB Scoring Machine For Making V Cut Line SMTfly-YB630

-

Fully Automatic V Scoring Machine , PCB Processing Equipment 1500kg SMTfly-YB1200

-

630*630mm V Cut PCB Scoring Machine 0-40m/Min Processing Speed SMTfly-YB630

-

0.4mm Thickness PCB Automatic Scoring Machine With Electronic Control System