|

|

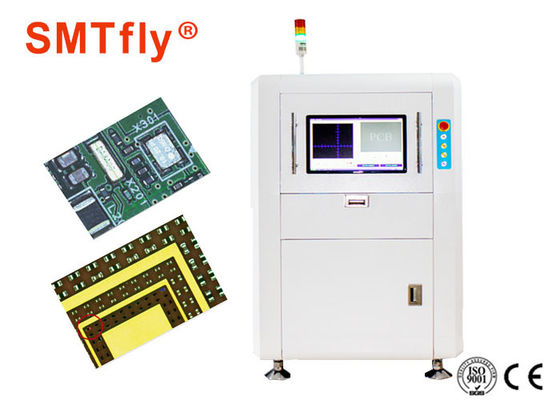

Multiple Function Automated Optical Inspection Equipment Simple Interface

Product Details:

Payment & Shipping Terms:

|

| PCB Thickness: | 0.3-3mm | Orientation: | <10um |

|---|---|---|---|

| Component Clearance: | TOP≤25mm,Bottom≤30mm | Use Environment: | Temperature 10-40 ℃ |

| Quality: | 10000COMPONET/PCBA | Air Supply: | 4-6bar |

| Highlight: | smt inspection machine,automatic optical inspection equipment |

||

AOI Inspection Machine-Customize Inline High Quality SMT AOI Machine,SMTfly-A586 Feature:

Multiple-Function

Different AOI model can be placed at several quality controlling points in SMT line such as to check 2D paste printing quality, Check component before reflow soldering, check PCBA quality after reflow soldering, and DIP after wave soldering

Simple Interface

Simple software interface accord with daily and effective operation

The work guide, makes the equipment to maintain consistently

The safe is comprehensive and nimble

The Lowest training request

Option and customized

Portable tracking doors design, easier for maintenance

With overspecialization it can meet different demands

The machine can work with OK/NG loader, make the seamless connection of on-line testing,PCB receiving and repairing

With the application of off-line programming and offline debugging ,m-acing the equipment with best value

Various algorithms applications and combination, make the application of software is more flexible

The new algorithm OCR and short test, meet the request of quality ins-software is more flexible

With high intellectualized control system, it can control the quality and give feedback in the first time

Fully meet the requirements of lead-free process

AOI Inspection Machine-Customize Inline High Quality SMT AOI Machine Specification:

|

Category |

Item |

Specification |

|||

|

Recognition system |

Inspection |

Using multiple algorithms synthetically such as WIDM Color image contrast technology color extracting technology,similarity,two-value handing technology,OCR/OCV etc. |

|||

|

Camera |

Distal and high speed color CCD camera:20um(15um/12um/10um for option) |

||||

|

Lamp-house |

Ring tower structure, high intensity RGB flash lamp-house |

||||

|

FOV |

Standard FOV:20*20mm,the maximum FOV:40*40mm |

||||

|

Image process |

0201 Cgip |

<9ms |

|||

|

Per-image time |

<150ms |

||||

|

Inspection Items |

Component Defects |

Missing , Misaligned ,overflow ,insufficient ,pasting open, stain |

|||

|

Solder Defects |

Missing,misaligned,skewed,tombstone,billboard,overturned,reversed polarity,wrong,damaged |

||||

|

Inspection items |

01005&0.3mm pitch()15um |

||||

|

Machine system |

PCB conveyor |

Substrate fixing method: bottom-up fixed, thimble function can correct large board bending. Automatic access to the board and automatic width adjustment system, in line with SMEMA standards. Track height of 900 ± 20mm |

|||

|

PCB size |

50×50mm~400×330mm |

||||

|

PCB thickness |

0.3-3mm |

||||

|

PCB warp tolerance |

2 mm (Fixture-assisted correction of deformation) |

||||

|

Component clearance |

TOP≤25mm,Bottom≤30mm |

||||

|

Machine system |

X,Y platform |

Driver |

AC server, camera moves in the directions of X/Y |

||

|

Orientation |

<10um |

||||

|

Moving Speed |

50mm/s |

||||

|

Soft system |

Operation system |

Microsoft Windows XP professional |

|||

|

Controlling |

Characteristics |

Set template images real time, count data and error gate value automatically , WIDM ,study ok template, input CAD date, Have the powerful function of feedback the inspect data and template library |

|||

|

Operation |

Graphic programming, Chinese English |

||||

|

Quality |

10000 COMPONET/PCBA |

||||

|

Network |

NG adaptable, check and correct PCBA defects at repair station |

||||

|

|

Computer |

CPU:intel dual-core,Memory:4G,harddisk:500G |

|||

|

Display |

19-inch LCD widescreen display / 19inch TFT |

||||

|

Others |

Air supply |

4-6bar |

|||

|

Machine Dimensions |

950*1000*1580mm |

||||

|

Weight |

580KG |

||||

|

Power Supply |

AC220V,10%,single phase 5A 50/60HZ,power consumption 1000W |

||||

|

Use environment |

Temperature 10-40 ℃, humidity 30-80% RH |

||||

AOI Inspection Machine-Customize Inline High Quality SMT AOI Machine Solution:

![]()

Contact Person: Sales Manager

-

Fully Automated Inline AOI Inspection Machine With 22 Inch TFT Display / CCD Camera

-

High Accuracy SMT AOI Machines , AOI Inspection Equipment Personalization Operate Design

-

500mm/S AOI PCB Inspection Equipment , Printed Circuit Board AOI Systems SMTfly-S810

-

700mm/S Speed Automated Optical Inspection Systems , SMT Inspection Machine Horizontal

-

AC Server Driver Automated Optical Inspection Machine 4-6 Bar Air Supply SMTfly-Z6

-

FOV 20*20mm PCB AOI Inspection Machine Work With OK/NG Loader 220V Power Supply